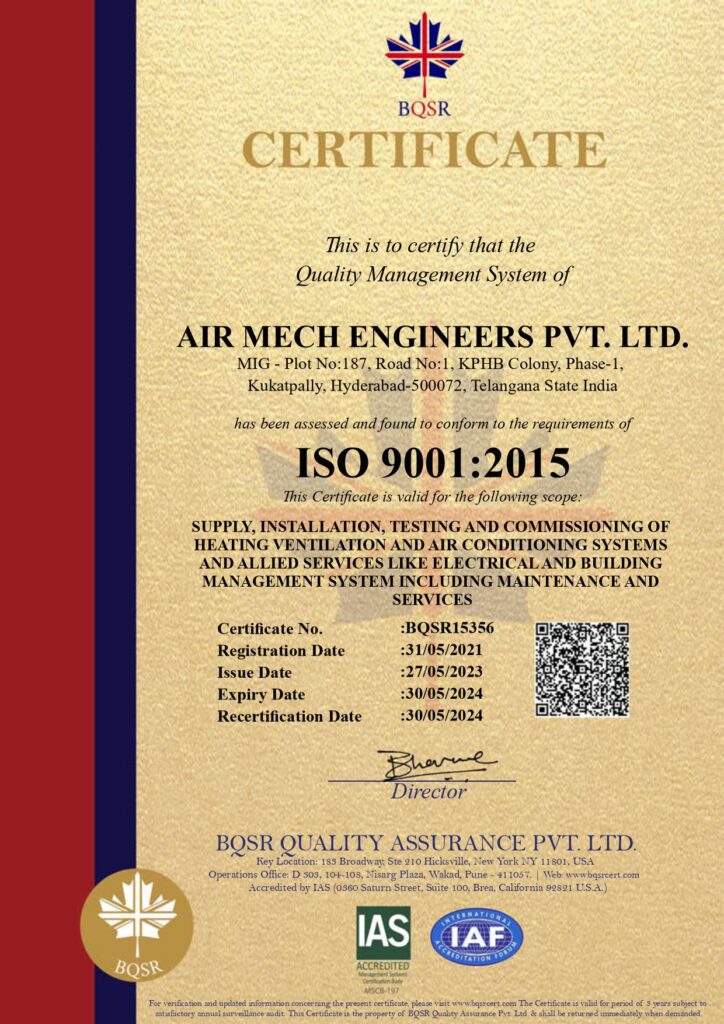

We at AIR MECH Engineers Pvt. Ltd., have adopted several methods like ISO 9001:2015 for quality control from our rich experience in project handling and trouble shooting.

The construction quality control process will comprise of storage of material, standard of workmanship, testing and checking of works.

In more specific terms, special focus will be given in terms of quality control for piping, ducting and insulation work, which are highly labour oriented activities. The procedures that would be followed will be listed out through method statement, which will be a basic standard to which work would get done. To ensure right quality there will be trained supervisors and foremen who will be deployed by us would be capable of controlling the quality of work.

All contracts are carefully reviewed and understood to meet customers’ need for their adequacy and our capability to meet customers’ requirements.

The Project Engineer proceeds to make detailed analysis of the various areas to be air-conditioned based on the drawing received from the Customer / Consultants / appropriate Agency and compares with the tender specs and offer.

Similarly, comparison is done for the equipment selection and system design.

Quality Policy

- The Project Engineer verifies the selection and approves selection if it is okay. Also based on primary data made available to us submittal is forwarded to Client / Consultant for their approval reg. Makes / type of equipment. The Project Engineer does the verification / selection of equipment based on vendors catalogues / engineering data.

- If any item / equipment / material is in customer’s scope of supply, the same is clearly spelt out and incorporated in design / drawing based on the engineering design data received from customer / consultant.

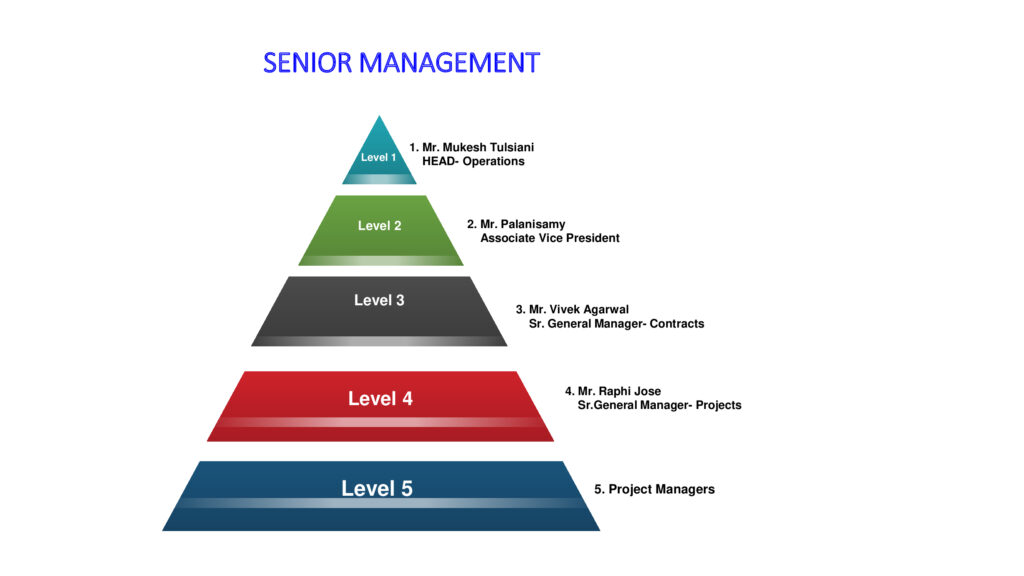

- A progress review meeting is held by General Manager and design team periodically to resolve all pending issues including review of the material submittal and drawing schedule.

- After obtaining approval from Client / Consultant / Construction Managers detailed orders are made.

- Records:

a.Contract Specifications

b.Design Calculation Sheet

c.Catalogue of various vendors - Retention period

a.Design calculations are retained in the job file

b.Vendors / manufacturers catalogues are updated as and when intimation received from vendor and are retained with Project Director.

ISO CERTIFIED ON QUALITY

1000+

Successfully completed projects

200Cr +

Revenue

200+

colleagues

25+

Year of experience